Kraus Group This is us

Kraus Elektrotechnik GmbH

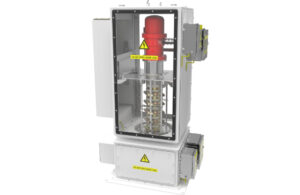

To this day Kraus Elektrotechnik – headquarter of the Kraus Group – has particularly focused on the construction and manufacture of slip rings. Over the last few decades, the company has become a globally known provider with high experience in development and manufacturing. Kraus Elektrotechnik additionally produces switches for rail applications, as well as equipment and spare parts for the electrical engineering field.

The company currently employs around 150 employees at its headquarter in Augsburg.

-

EKR Elektro-Kontakt Radebeul

Current leads, ground straps, brush holders and electromechanical spare parts in a wide range of standard and customised versions: These represent the core competencies of a team of around 30 employees at EKR Radebeul in Dresden. As member of the Kraus Group since 1993, the small but flexible company completed a modernisation and restructuring process to establish itself as a long-term specialist for these products. Excellent performance standards and on-time deliveries are not least the result of our quality management system created in accordance with DIN EN ISO 9001.

Details -

Kraus Kunststofftechnik

As a specialist for plastic components, Kraus Kunststofftechnik GmbH has complemented the Kraus Group´s product portfolio with many components of consistent and excellent quality since the eighties. Based close to Augsburg, the subsidiary also enjoys a client base that it independently supplies with duroplast parts moulded from BMC and SMC in diverse press and injection moulding processes, as well as thermoplast, injection moulded, parts. Our experienced, highly qualified personnel benefit from a modern machine park and ensure consistent quality from pilot or small series to high volume series production.

Details Kraus China

Kraus China is our gateway to the far-east market. Our Chinese subsidiary in Tianjin near Beijing was founded in 2007. Specialised in the design and manufacture of products for railway applications they concentrate on the production of disconnectors and earthing switches for the asian market.

Climate Neutral Company

Climate change might probably be the biggest challenges for human kind since the end of the glacial period. It is now on us all to keep down the deterioration of our climate.

The economic choices and actions in industrial countries like Germany play a major role in the fight against growing emission. As a part of this industrial community we are willing to take over responsibility for earth as we leave it to our children and grandchildren.

Consequently we have decided to record our company’s greenhouse gas emission, which we are gradually trying to reduce now. As a comprehensive reduction of emission can hardly be realised, we are compensating the remaining emission by means of climate protection certificates, through which we support three valuable projects: A wind power project in Jaibhim, India, a reforestation project in Uruguay and a project improving cooking stoves in Ghana.

Technology and Quality Made in Germany

“Made in Germany” technology enjoys an excellent reputation worldwide. This is partly due to a long tradition of training engineers and educating technically qualified personnel. With its high density of medium-sized companies, Germany also has an exceptionally dynamic business environment with cross-industry synergy effects.

Since it was founded in the fifties, the Kraus Company has been a fixed component of this dynamic. At the same time, we have continuously developed our products and services to set the standards of our industry segment, particularly in the field of slip ring systems. However, we have also been able to maintain the flexibility and vitality in our development as a medium-sized company. We provide the quality meant by “Made in Germany” – always giving and benefitting in equal measures.

Our regional and international clients and partners benefit throughout from the high standards of our duty to service and quality.

In accordance with DIN EN ISO 9001, we have implemented comprehensive quality controls and a firmly integrated system of management processes. In addition, our many patents for certain product applications ensure our developmental edge.